Custom Powell Lens System Design

Laserline Optics offers design and fabrication services for laser illumination systems for a broad range of industrial, scientific and research applications. We are pleased to have Dr. Ian Powell, the inventor of the Powell lens, as a key member of the Laserline Optics design team.

Lens Dimensions

The Laserline Optics 0.35″ (8.89 mm) diameter and 0.3″ (7.5 mm) nominal height Powell lens, manufactured since 1994, has become the industry standard dimension. Other dimensions and shapes are possible for custom applications.

Line Uniformity

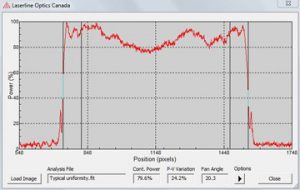

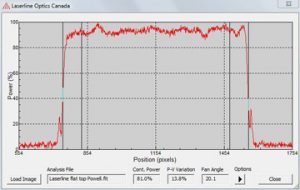

Most applications are well served by our standard Powell lenses. For demanding applications we offer highly finessed lenses with tight specifications on line uniformity and contained power.

Standard precision stock Powell lens uniformity

High precision “Flat Top” grade Powell lens

A laser lines’ measure of uniformity often varies with the application. Small fan angle Powell lenses require a uniform line since the target is illuminated nearly square on. Large fan angle lenses producing long lines in a short distance may require more energy at the line’s ends in order to compensate for reduced back scatter to the imaging system. Applications requiring specific energy distribution along the laser line are easily accommodated.

Powell Fan Angle

Laserline Optics Canada stocks BK7 lenses with 1°, 5°, 10°, 15°, 20°, 30°, 45°, and N-SF6 (or equivalent) 60°, 75° and 90°. LOC can also manufacture custom fan angles with low non-recurring engineering costs. Substituting the standard substrate with a higher or lower refractive index glass is an economical way of producing a custom fan angle for low volume orders. For example, substituting F2 glass (n=1.6) for the standard 5° BK7 Powell will yield a 7° fan angle.

Special Substrate

Standard optical glass is suitable for most applications, but Powell lenses subject to corrosive chemical environments or requiring broadband wavelength transmission call for careful substrate selection. Fused silica is ideal for its broadband transmission properties and relative insensitivity to chemical attack. All lenses fashioned from standard optical glass change their shape and thus line uniformity with large temperature changes. Applications with high precision line uniformity requirements and subject to high temperatures may utilize zero expansion glass ceramic substrates such as Schott’s Zerodure or Corning ULE. Laserline Optics’ production process can easily accommodate any substrate with low non-recurring engineering expenses.

Coating

Laserline Optics stock lenses are not coated. Coated lenses for specific bandpasses are available on request at additional cost.